- April 19, 2024

-

-

Loading

Loading

On the front lines, health care workers and first responders are among those risking their health daily to ensure others are taken care of during the coronavirus pandemic.

But behind the scenes, there are other heroes doing their part to help protect those essential workers who cannot stay home.

In Baldwin Park, residents are making fabric face masks and plastic “ear saver” pieces for their friends, neighbors and community at large.

Dr. Ester Lincourt has been putting her sewing skills to good use lately. A retired obstetrics and gynecology doctor of 25 years, she also has been sewing since she was a little girl.

“I was making clothes for my Barbie dolls from scraps of fabric (left from when) my mom had made clothes (for me) so we’d be matching,” Lincourt says. “Going into retirement, I picked up making quilts and was always sewing.”

Lincourt also takes yoga classes from Lifestyle Director Becca Schmidt. During one particular yoga class, her fellow classmates discovered she could sew.

“Becca made some kind of comment at one point during yoga when they found out that I sewed, and I go, ‘Of course, I’m a surgeon, I have to know how to sew!’” Lincourt says, laughing.

"We all have God-given talent, and sometimes we don’t know what those talents are. Who’d have imagined I would be able to use my surgeon skills and apply it to this pandemic we’ve been having?”— Dr. Ester Lincourt

The idea to use her skills to sew masks came from a friend in West Virginia, who in March posted a photo of her sewing machine and mask-making process. The friend couldn’t get surgical masks for her office and wanted to have some fabric ones on hand for her staff.

Lincourt learned there also was demand for the masks locally. Using donations of fabric and elastic, along with what she already had on hand, she began making masks for former colleagues at Women’s Care Florida.

“I made masks for our office, and they started handing it out to family members, and then neighbors got word of it,” Lincourt says. “I said, ‘You know, as many people as I can, I want to cover and protect because even though they’re not N95 makes, it’s still a barrier.’ You can actually make the barrier even better with making a filter in between (the fabric pieces), whether it’s a coffee filter or an A/C filter. The higher MERV index it has, it actually blocks particles holding viruses and bacteria.”

Lincourt’s masks are made with a slit to slide in a piece of filter paper, as well as a wire at the top to bend over the nose for a better fit. So far, she has made nearly 300 masks.

Her masks have gone to staff and patients at her husband’s doctor’s office, friends, neighbors and various health care organizations. She even gave one to her Shipt grocery delivery shopper.

“They’re overwhelmed; they can’t believe we’re thinking of them to make these and help,” Lincourt says. “I’ve gotten a lot of positivity out of it. Since we’ve been on house arrest, I’ve used Shipt to do my Costco shopping. … I had this idea. I thought, ‘I’m going to give this one mask to the girl delivering my groceries.’ I put it in an envelope outside the garage door where she was going to drop off my groceries. She was literally in tears, and she had taken a picture and sent it to me on her phone and she said she’d already gotten compliments from her next customer.”

Lincourt isn’t charging anything for the masks; rather, she is doing it to help protect the community. There still are many people who need masks, and that hasn’t gone unnoticed. In fact, Lincourt says, she has started to pray over her masks, asking God to protect those wearing them.

“We all have God-given talent, and sometimes we don’t know what those talents are,” she says. “Who’d have imagined I would be able to use my surgeon skills and apply it to this pandemic we’ve been having? The fact that I’m sewing and am creative and can put this together … that’s a God-given talent, and he will tell you when to use them. My job is to embrace it and take it and run with it.”

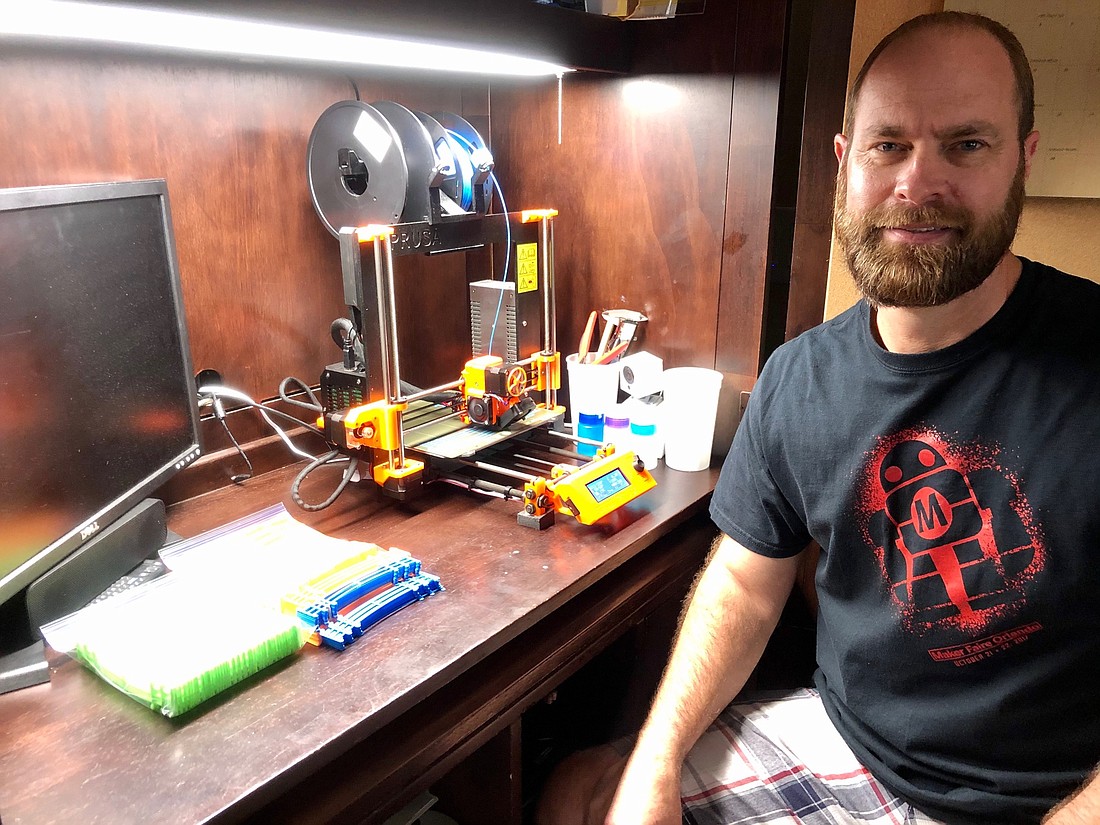

Also in the neighborhood, Jason Chapman has kept himself and his 3D printer busy by creating what many are referring to as “ear savers.”

These small pieces are made of PLA plastic, the most widely used plastic filament material in 3D printing. Their main purpose is to help protect the ears from chafing while wearing a medical face mask — a common problem thousands of health care workers and first responders have been facing these last few weeks.

Wearing a mask with elastic straps for hours can cause irritation behind the ears. The ear savers act as a place for the straps to hook onto, usually at the back of the head.

Chapman has an engineering background and has owned his 3D printer for nearly three years. Although he’s used to creating knick-knacks and functional parts to replace things around the house, he switched over to printing about 100 to 150 ear savers per day.

“I saw an article about them on Facebook and thought it was interesting, but then I actually had a neighbor who owns Lombardi’s Seafood request 40 of them for their staff,” Chapman says. “I wrapped those up. Then, I’ve got a friend who has the same printer as me, and he has a couple of nursing friends who started requesting them, so he was printing a bunch for them. I reached out to a couple hospitals and … I put a post on NextDoor, and it’s kind of gone crazy.”

As of mid-April, Chapman has made about 1,300 ear savers. He’s also printing a different variation of the product that uses less material. So far, he’s only used up two spools of filament to create 1,000 ear savers.

“I have accumulated a pretty good supply of various colors over the years, so I have probably 15 or 20 rolls of (filament),” he says. “I’ve got many more to go before I run out.”

Chapman is donating every ear saver he makes. Some have gone to AdventHealth locations, some to the UF Health Cancer Center and others to Publix, as well as various health care organizations in Central Florida. He even placed some in a Tupperware container on his front porch for any neighbor who needs one.

“I have one doctor made the comment, ‘It’s really a need for something that no one knew was a problem until now,’” Chapman says. “It was one of those things people didn’t really think about until they started wearing masks for a long period of time. It’s something that will help alleviate the discomfort. Everybody’s been very appreciative, and it’s something I can do for the cause while I’m stuck at home myself.”